LiquiShift Variable Rate Technology

Why Metering Tube?

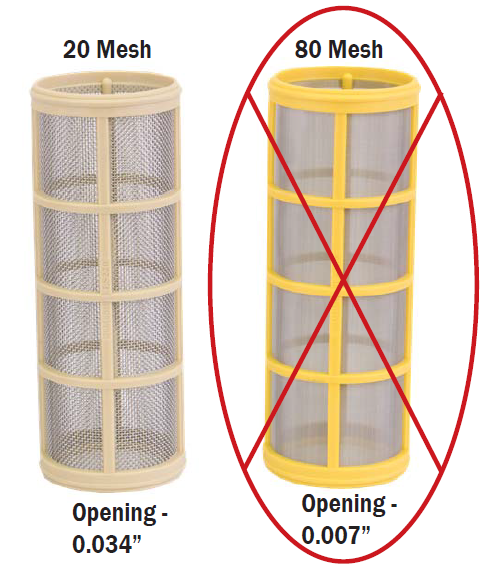

SureFire loves to use Metering Tube in place of a traditional disc orifice to provide even distribution to each row. In a typical in-furrow application scenario, a 0.030″ orifice is replaced with an 8′ length of metering tube having a passageway of 0.096″. The combination of length and diameter equalizes flow to each row. Metering tube eliminates the problem of plugged orifices and the need to run small strainers to keep small mechanical components and orifices from plugging. Metering tube size varies from 0.080″ to 0.187.” With Metering Tube, just a 20 Mesh Strainer is needed to “get out the big chunks!”

Why LiquiShift®?

LiquiShift® Variable Rate Technology provides the ability to achieve the widest range of on-the-go rate changes of any application system available. SureFire’s LiquiShift® will allow for a flow increase of 6-8 times the minimum flow rate the system is configured for. In a scenario with a minimum rate of 10 GPA at 4 MPH, the maximum rate at 6 MPH would be 40-50 GPA (6-8 times the minimum rate).

LiquiShift® allows the installation of two metering tubes on each row. Special software developed by SureFire monitors the system pressure and automatically shifts between the two metering tubes on each row, keeping the LiquiShift® plumbing package in a pressure sweet spot.

Prescription Applications

Achieve your agronomic objectives without limitations. You will no longer narrow the range of your liquid prescriptions to get within the achievable range of a single orifice size. With 6-8 times flow capacity your agronomist is in the driver’s seat. When the analysis calls for 8 GPA in low-productive or areas with high residual nutrients, you will apply 8 GPA. When the analysis calls for 45 GPA in the high productive “black-soil” region of the field, you will apply 45 GPA. No longer will you be forced to over-apply in the poor performing areas.

Application Rate Changes from Field to Field

Never change another orifice. LiquiShift® utilizes metering tube to achieve uniform row-to-row accuracy and automatically switches between tubes to allow dramatic rate changes from field to field. Simply set the rate in your controller and LiquiShift® automatically chooses the proper metering tube.

Speed Changes/High Speed Planters

Faster application and/or planting speeds require larger flow ranges from your liquid application system. High-speed planters designed to work at 8-10 MPH impact fertilizer flow rates by a factor of 1.5-2. High-speed liquid applicators and side dress machines create a similar scenario. LiquiShift® is ideal for all of these high speed scenarios.