SOIL-MAX

Gold Digger

Do you want to install drainage tile but fear the investment of doing it yourself? The Gold Digger® makes tiling affordable and effective. Utilizing the tractor you already own and our cutting-edge, user-friendly tile plow, you can tile your land for 1/3 the price of outsourcing the job.

Gold Digger Stealth ZD Tile Plows

- Manufactured from T1 Steel, allowing twice the tensile strength with half the weight.

- 2 ¼” of t1 is = to 6” of mild steel in strength.

- Thinner profile shank = easier pulling through the soil.

- Lifting action lifting soil through the entire soil profile to make less drag on the plow.

- Installation of 3” to 10” tile by changing quick change poly sided boots and shear.

- Trapezoidal shaped shear and contoured boots to match tile size and maintain tile trench from beginning to end for accurate pipe placement.

- Zero deflection produces better grade control with the tile exit point directly below the hinge point of the pitch plow.

- Proprietary proportional valve to make crucial incremental adjustments to keep your plow on grade.

- Available options: PWM controlled tile feeder, walking tandems.

Tile Drainage Revolutionized

The Soil-Max® Gold Digger® is unlike any other agricultural drainage plows on the market, producing unparalleled economic and environmental benefits.

Unlike the Gold Digger® , other tile plows on the market aren’t made from T1 steel. T1 steel is strong and thin and thus easier to pull than plows made from thicker types of steel.

Unlike traditional designs, the Gold Digger® has a 3-point hitch that is in float, keeping the tractor completely independent of the plow. This unique design translates into reliable grade control even with less-than-perfect surface conditions.

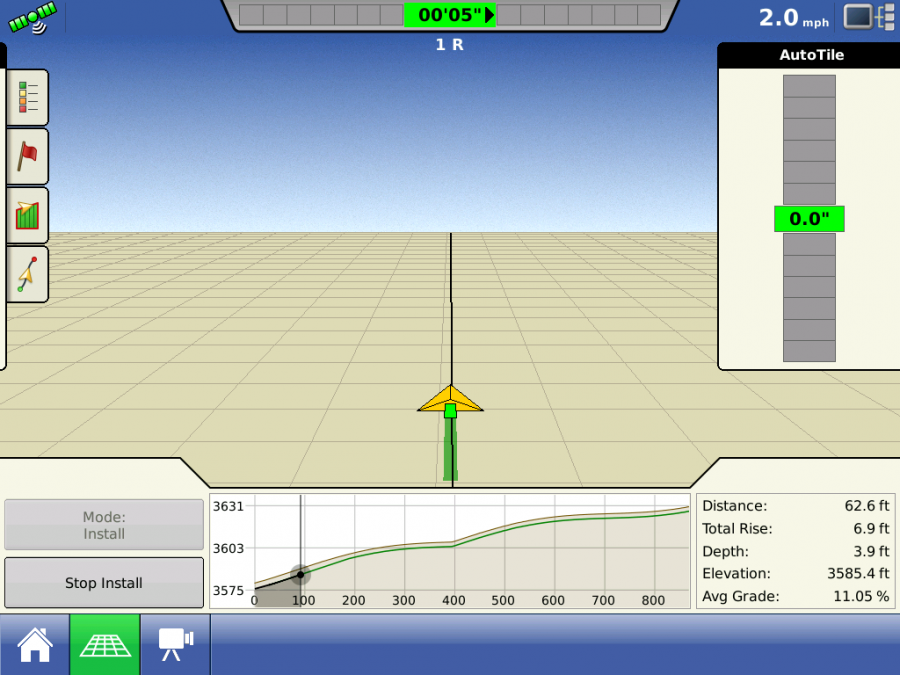

Intellislope

Ag Leader’s Intellislope® simplifies the process of installing farm drainage tile through its RTK GPS receiver, which installs tile on grade throughout the entire run. Laser surveying equipment and adjustments during tiling are obsolete. The Intellislope makes the process more accurate and reliable, no longer subject to fluctuating weather conditions or grade variations in changing topography.

AutoTile

Survey

Can be done ahead of time with an ATV, or at the time of installation with the tile plow utilizing RTK GPS. Collect surveys by driving over the path where tile needs to be placed to collect the surface elevation.

Plan

Enter the desired minimum/maximum and target depths, as well as the minimum grade to drain excess water from the field. This can be done in the field or with the SMS TM Advanced Water Management Module.

Installation

Use the plan you created to install tile using AutoTile® to adjust the depth of the plow automatically. Grade control or pitch control modes can also be used as needed.

Soil-Max HD Cart

Soil-Max® HD tile stringer carts improve productivity with their smart design and broad tiling range. They simplify tile spool transport and feeding so you spend less time in transport and set-up and more time tiling.

Design Features

Commercial Grade Design

The Soil-Max® HD Cart is built to handle the rigors of rugged terrain. It has a sturdy 5,200 lb. axle on 6-lug wheels with a steel tube construction frame. A 30-foot magnetic controller and 12V DC hydraulic unit makes operating the unit simple and straightforward. Standard onboard charging system.

Flexible Feeding

The 11′ 6″ tabletop diameter with disk brake turntable makes feeding tile similarly easy and the 12-inch diameter stringer can manage the flow of any size tile. Add the optional wireless controller, and dont mess with wires to the cab again.

Soil-Max® makes managing your tile easy with hydraulic control of the table. Optional wireless remote makes cumbersome wires, or rope brakes a thing of the past. Standard features of high flotation tires, large table, large stinger, heavy built frame, and onboard battery charger makes the chore of stringing tile a breeze.

Soil-Max Shaper Pro

Built from the ground up with one goal in mind the Shaper Pro will make quick work of soil heave or trenches left behind after tiling. With its one of a kind design, the Shaper Pro resizes and relocates tile heave right back over the center of your tile. Shapers Pro works on all soil types and even in tough grassy areas.

Double Helix Rotating Blades

Our specially designed T1 steel blades not only resize but reposition chopped up soil right back over your tile. With 36 different blades spinning at 250 RPM large chunks of soil are chopped up and relocated in seconds. Every 3 sets of blades, starting from the outside, the blade angles change ensuring that the soil is being repositioned right where it needs to be. With a 24” rotating diameter the Shaper Pro can take on all sizes of heave.

Fully Adjustable Backdoors

After the soil heave has been pulverized by the rotating blades the fully adjustable doors ensure that existing soil is right over your tile. With two cylinders controlling the blades, all adjustments can be made on the go from inside your tractor cab. This is important because tile heave changes depending on the depth of the tile, soil type, size of the tile, and even soil condition. Wet, dry, sandy, and clay soils can all be found in one tile run. With the fully adjustable doors, adjustments can easily be made on the go to work with all types of soil and soil conditions.